CASE STUDY

Destructive Internal Vibrations in Natural Gas Fired Boiler

| PLANT LOCATION | Asia |

| FACILITY DESCRIPTION | Gas Refinery Plant |

| BOILER TYPE | Bi Drum – Watertube |

| BOILER CAPACITY | 120 [Tonnes/hour] |

| STEAM CONDITIONS | 60 [Bar] @ 510 [°C] |

Conditions:

A natural gas fired high pressure boiler recently installed in a gas refinery had been experiencing major vibration problems which limited the boiler’s ability to achieve its maximum rated output. As was typical of boiler vibration issues, the problem exhibited a threshold load below which the vibration did not occur.

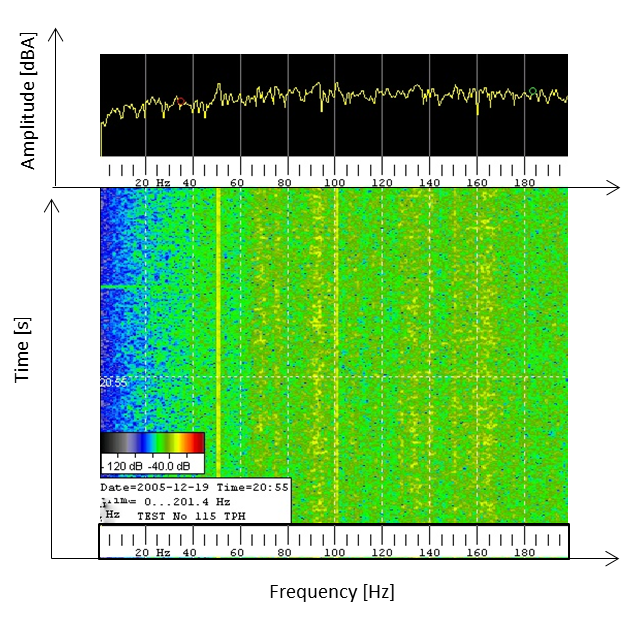

Design Boiler were engaged to investigate the problem, identify the cause and to provide a solution. A Design Boiler engineer was mobilized to the site where he subjected the boiler to a series of boiler performance tests which included recordings of the actual vibration.

Design Boiler quickly identified a series of potentially destructive frequencies which could be related to the principal dimensions of the boiler furnace. There was also clear evidence of secondary frequency peaks which indicated that the disturbance was harmonic. The natural frequency of downstream tube banks and other possible contributions of boiler vibration were investigated however these could not be related to the offending frequencies. This suggested that the vibration problem originated from within the boiler furnace.

An analysis of the burner indicated that the orientation and depth of the burner blast tube (shown below) was probably generating the offending furnace vibration frequencies. New burners with different dimensions outside the dangerous harmonic range were installed in the unit, following which the boiler was able to operate over its entire operating range without any vibration issues.