CASE STUDY

Downcomer Instability | Turbine Scaling and Sand Blasting Damage

| PLANT LOCATION | USA |

| FACILITY DESCRIPTION | Metal Processing |

| BOILER TYPE | Bi Drum – Natural Circulation – PC Fired |

| BOILER CAPACITY | 250 [Tonnes/hour] |

| STEAM CONDITIONS | 62 [Bar] @ 470 [°C] |

Conditions:

The commissioning of a new 250 [TPH] high pressure boiler could not be completed because of ongoing problems with the drum level control system. The boiler also exhibited a number of other unusual problems including a significant variation in drum level between the left and right hand side of the drum. The boiler was a pulverized coal fired natural circulating bi drum unit producing 62 [Bar] steam at [470] °C. It was fitted with a three-element drum level control system but irrespective of whatever control settings were made the drum level would initially exhibit a measure of stability only to become erratic and uncontrollable during subsequent operation.

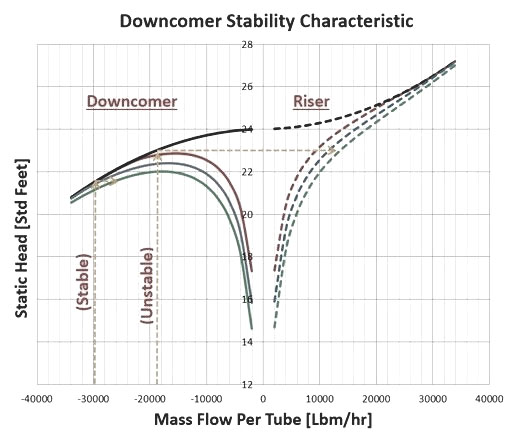

A boiler circulation analysis by Design Boiler identified a downcomer instability issue as the probable cause of the problem. The internal steam drum baffle plate was incorrectly located along the steam drum which allocated too many of the heated convection bank tubes as downcomers. Some of the allocated downcomers were reversing and forming a boiling zone on the drum level surface. The boiling zone generated a false drum level which was erratic and could not be controlled by the control system.

The boiler was subjected to a series of tests to verify the downcomer instability finding resulting from the circulation analysis. An online sodium analyzer was installed and connected to the main saturated steam pipe at the point where it exited the steam drum. Because most water treatment programs introduce chemicals that contain sodium, sodium detection is an ideal indicator of carry over. Subsequent analysis of the tests identified a clear correlation between the indicated drum level instability and the detected sodium levels in the steam, thereby concurring with the findings of the circulation analysis; that drum instability was due to poor boiler circulation.

Design Boiler ’s computer model that was configured for the circulation analysis was used to identify the new position of the steam drum baffle plate needed to maintain the correct allocation of heated downcomers tubes necessary for stable drum level control. Following the baffle modification, the boiler was returned to service and its drum level was able to be controlled without difficulty.

It is relevant to note that other operational issues can also be generated or affected by Downcomer Instability. Some examples include excessive turbine blade fouling and internal scaling of superheater surfaces.