CASE STUDY

Biomass Fired Boiler | High Particulate Emission & Boiler Load Limited

| PLANT LOCATION | Asia |

| FACILITY DESCRIPTION | Bio Fuel Production Plant |

| BOILER TYPE | Bi Drum – Watertube |

| BOILER CAPACITY | 45[Tonnes/hour] |

| STEAM CONDITIONS | 36 [Bar] @ 310 [°C] |

Conditions:

A biofuel plant had purchased a 45 T/hr boiler from a leading boiler manufacturer to generate electricity through a small steam turbine at their production facility. However, the plant owners believed that the boiler was unable to achieve its Maximum Continuous Rating (MCR) and that its particulate emissions exceeded statutory limits. Design Boiler was engaged by the boiler manufacturer to provide an independent opinion.

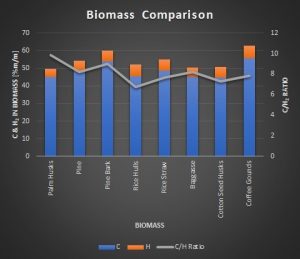

Through careful stoichiometric assessment Design Boiler was able to show that the H2O and CO2 levels specified in the particulate emission testing were inconsistent with the chemical composition of a typical biomass fuel and therefore the validity of the test results was highly questionable.

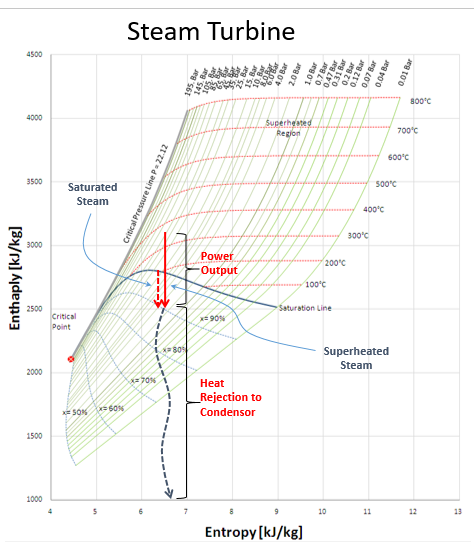

Design Boiler was also able to demonstrate that the steam flow meter upon which the load limiting claim was based was defective. This was achieved by carrying out an isentropic assessment of the steam turbine performance through which all of the steam from the boiler passed. Because the electricity generated by the turbine was accurately measured it was possible to correlate this generation to an equivalent steam flow by applying thermodynamic principles. This analysis categorically proved that the steam flow meter was in error and was also able to explain why the boiler appeared to be unable to achieve its Maximum Continuous Rating. A subsequent inspection of the steam flow meter established that the probable root cause of its inaccuracy was its close proximity to the turbine which allowed turbine vibration to detrimentally affect the steam flow meter.

The matter was resolved once these facts were presented to the boiler owner. The flow meter was relocated away from the influence of the turbine vibration and a new isokinetic sampling contractor tested the particulate emissions of the boiler and established that contrary to the previous tests, they actually did comply.