CAPABILITIES

Boiler Dynamic Analysis

Design Boiler have developed software that is able to simulate the dynamic response of a boiler control system to rapid changes in boiler load.

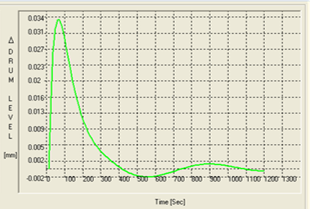

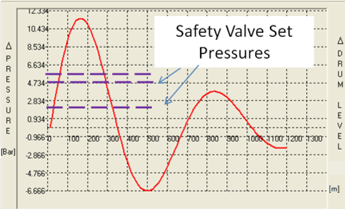

Sudden changes in steam demand can cause rapid rises in steam pressure that may lift safety valves. The lifting of safety valves may then lead to a sudden drop in boiler pressure causing drum level instability and this can trip the boiler on high steam drum water level.

The ability to recover from this type of upset condition depends on a boiler’s control settings, it’s thermal inertia, steam drum size and combustion system capacity.

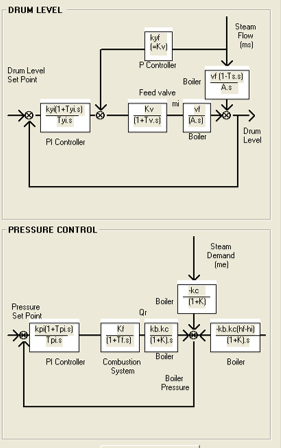

Our Boiler Dynamic Analysis software is able to model a boiler control system’s response to these types of upset conditions and test drum level controller settings. It can also assess a boiler’s capacity to meet sudden steam demands from downstream users, which may be a simple question of short term thermal capacity.

A typical scenario that could benefit from our boiler dynamic analysis software is discussed below:

SCENARIO:

A boiler experiences frequent drum level trips in response to the discharging of superheater safety valves caused by frequent and sudden changes in the steam demands of a downstream process.

METHODOLOGY:

Site Data Collection:

- Information such as control room operating data, boiler geometric details along with general information about the boiler controls and combustion system is obtained from site.

Analytical Modelling:

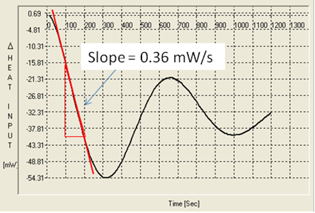

- Specific input parameters utilised by the software are then derived. These include the “Boiler System Time Constant” Ts determined from boiler circulation theory, boiler steel and circulating water masses, along with other relevant system constants.

These parameters are used by our Boiler Dynamics Software to model the drum level control system response for a range of drum level control settings and upset conditions including sudden changes in boiler steam demand. In this way, optimum settings that minimise potential high drum water level trips following safety valve discharges and other disturbances are derived.

Implementation

- The findings from the dynamic modelling are used to revise the boiler control system parameters which are then commissioned and fine tuned on site.