CAPABILITIES

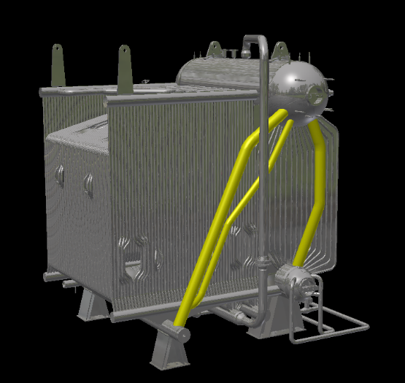

Oil to Gas Firing Conversion

Design Boiler is skilled and experienced in undertaking the necessary computer modelling , design work and field testing required for converting oil fired boilers to gas firing. A typical oil to gas firing conversion scenario is as follows:

CASE STUDY SCENARIO:

An oil fired Marine boiler on an off shore Floating Production Storage & Offloading [FPSO] platform is required to be converted to allow firing on gas. Design Boiler receives a request to carry out the necessary redesign of the boiler and prepare relevant documentation to submit to a marine class authority ( ABS, Lloyds, DNV etc.)

METHODOLOGY:

Site Visit:

1..Collect operating data, boiler geometric information and specifications .

Boiler Performance Modelling:

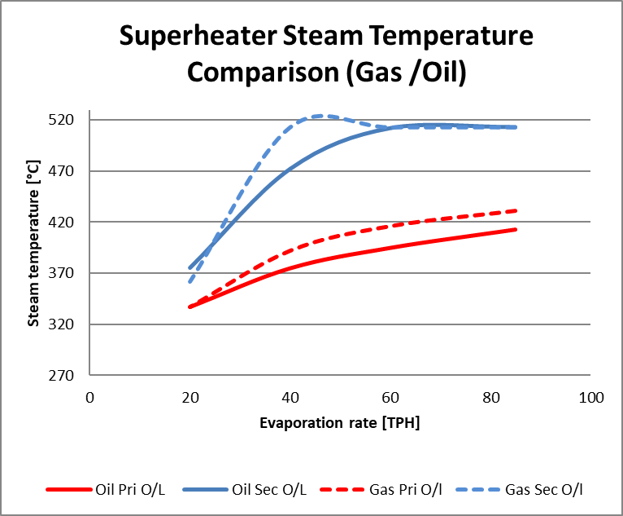

2. Undertake computer software modelling to simulate boiler performance over a range of load scenarios when firing both oil and gas.

Analysis:

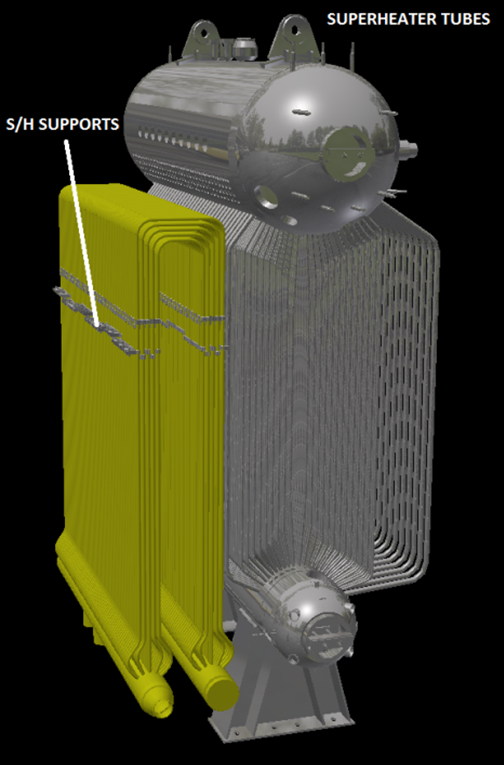

3. Identify any issues that could generate high steam temperatures which may limit the boiler’s output on gas. Limitations caused by high steam temperatures might require (i) an upgrade in the grade of tube metal, (ii) a reduction or reconfiguration to the superheater heating surface or, (iii) modifications to the attemperator cooling coil. The boiler’s sensitivity to variations in excess air requirements is also modelled.

4. Assess possible solutions to any problems identified by the computer model including assessment of steam temperature sensitivity to variations in Excess Air requirements.

A case study demonstrating our Oil to Gas Firing Conversion capabilities can be found here.