CAPABILITIES

Steam Cycle Optimisation

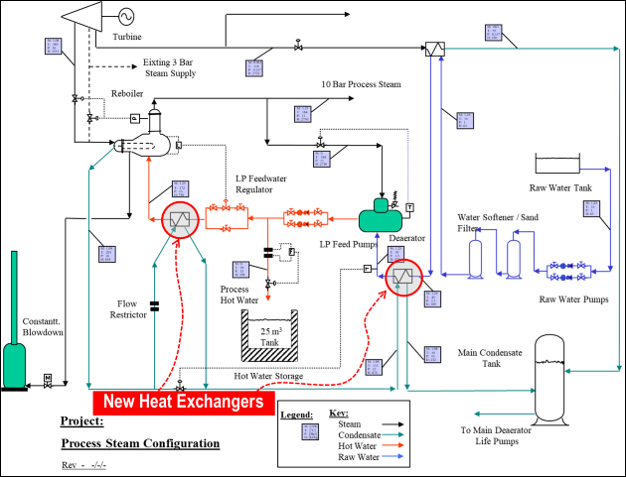

A poorly designed or problematic steam cycle can impact on overall plant efficiency and significantly increase energy costs. High flash steam losses and excessive condensate makeup are all symptoms of a badly balanced steam cycle which can have detrimental effects on the performance of downstream appliances such as deaerators and steam turbines.

Design Boiler is skilled and experienced in the design and optimization of steam cycles on both marine and industrial installations. We have the necessary resources, skills and experience to identify and address most issues that are likely to be encountered with marine, off shore and industrial steam cycles. A case study demonstrating this capability can be found here.