CAPABILITIES

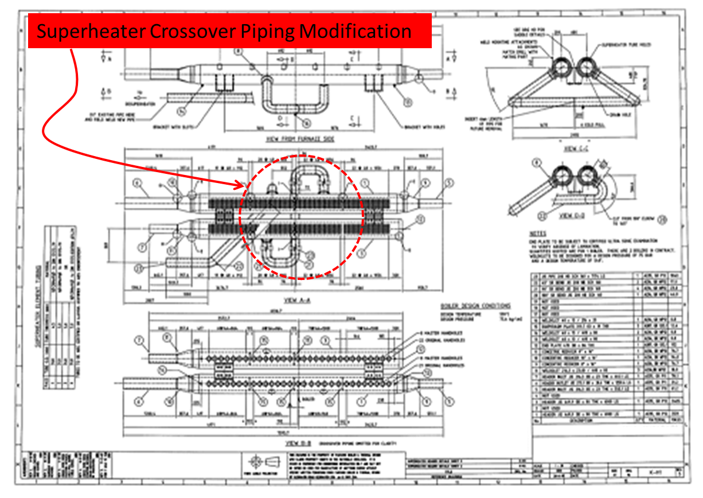

Superheater Design

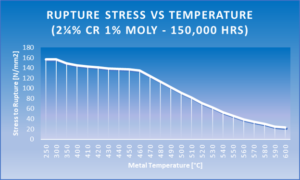

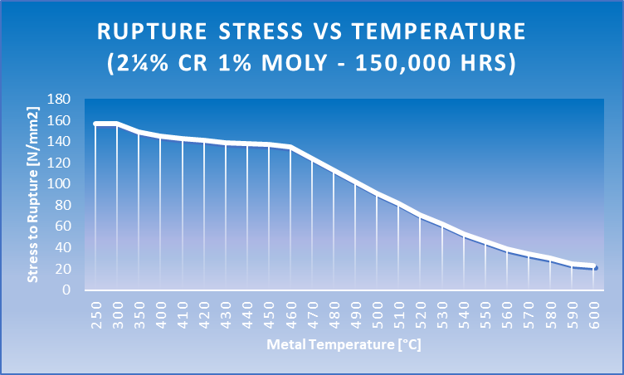

Superheaters operate within a very arduous environment and are often designed at the extreme end of their tube’s metallurgical limits. As well as being the first receiver of the hottest flue gases generated within the furnace, they are constantly subject to direct radiation from the combustion process. Most boiler design standards (ASME, BS, ISO, Lloyds, ABS etc) require the superheater to be designed to achieve a minimum design life in terms of operating hours. For example, BS & ISO standards require the superheater to be designed for a minimum of 100,000 hours. This requires the likely metal temperatures that the superheater will be subject to during normal operation to be determined and that an appropriate tube material is selected to withstand those temperatures.

The furnace environment is thermodynamically chaotic and calculating maximum superheater metal temperatures is a specialized field. Design Boiler has extensive experience predicting superheater metal temperatures for the purposes of either diagnosing causes of premature tube failures, or reviewing the existing design of superheaters subject to changes in operating conditions or fuels.

A case study demonstrating this capability may be found here.