CAPABILITIES

Economiser Design

Their is an ever increasing demand on plant operator to reduce fuel consumption boiler plant. Reduced fuel consumption with higher plant efficiencies not only lowers operating costs, it also reduces emissions. Economiser are sometimes the only effective way to achieves cost effective fuel savings but the installation of an economiser can have a significant impact on the operation of the boiler and needs to be designed by experts. Some common issues that are overlook in the design of many economisers include:

- Increasing the feedwater temperatures into a boiler can have a significant impact on the internal circulation within the boiler. For example Bi-drum boilers rely on the sub-cooling of feedwater to (a) mop up micro steam bubbles expelled from the steam separation system, and (b) to allow heat to be absorbed within the heated boiler bank downcomers that form an integral part of the bi-drum boiler circulation configuration (see example here) .

- Effective strategies are required to ensure the even distribution of feedwater within the internal surfaces of the unit. If this issue is not addressed the economiser can steam resulting in depleted performance, steam carry over that can potentially damage downstream superheaters and appliances, and significantly damage the economiser banks. Economiser can also steam as a result of poor design and this can have similar detrimental effects.

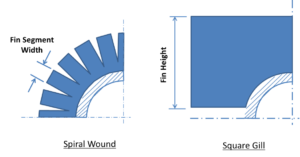

- The extended finned heating surface has to be carefully selected. Spiral wound finned surface works well with gases but it is not suitable for operating on boilers firing oil or solid fuels such as wood waste or bagasse. Uncombusted material can get trapped in the space between adjacent fined tubes, catch fire and result in a highly destructive catastrophic metal fire (see example here).

- Square gill (typically H fin) or plain tube economisers are the most suitable for solid fuels that require regular cleaning. Plain tube economisers are thermally relatively inefficient and relatively large and expensive. There are only limited companies that can evaluate the thermodynamic performance of square gill economisers and this type of tubing is relatively expensive. The pros and cons of each option have to be carefully accessed.

- Draught loss consideration are an important factor when designing economisers particularly when a unit is to be retro fitted to an existing boiler. Ideally the economiser must be designed to ensure that its gas side pressure loss can be accommodated by the existing boiler fans.

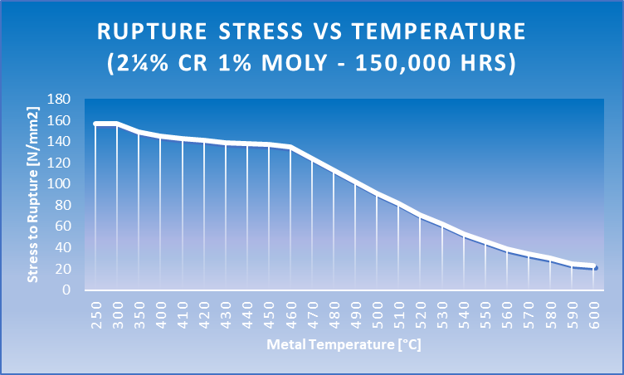

- Economisers operating in boilers that fire fuels with high sulphur contents, such as oil or high sulphur coal, need to incorporate special precaustions to protent them from dew point corrosion damage. Whilst economisers are not normally as susceptible as air heaters, they can still operate at metal temperatures lower than the prevailing flue gas dew point which makes them potentially vulnerable to corrosion damage.

Designing an economiser to achieve these objectives requires both qualified design engineering personnel, with extensive experience and access to comprehensive boiler and economiser modelling software. We are also able to model and design economisers constructed from square gill tubing.

Design Boiler have qualified personnel, with the necessary experience and computer resources to design new economisers for retrofitting to existing boilers or to install onto new plant.