CAPABILITIES

Boiler Tube Bank & Furnace Vibration

Vibration can impose major restrictions on a boiler’s steam generating capacity and inflict significant long term structural damage. Typically vibrations will occur above a distinct threshold load or within a very narrow operating load range. If the boiler is operated above or within this load profile for extended periods, it can sustain substantial damage.

There are 3 main causes of boiler induced vibration:

- Abnormal pressure pulsations generated at the burners;

- Furnace harmonics; and

- Flow induced vibrations across tube banks.

The major challenge in addressing boiler vibration problems is identifying the likely source of the vibration and this normally requires some form of on site vibration monitoring and expert analysis. Once identified there are often relatively simply strategies that can be implemented to resolve the problem.

A typical investigation would proceed in accordance with the following process:

SCENARIO :

Plant Load is limited due to vibration that occurs within a specific load range of the boiler.

METHODOLOGY:

Site Testing:

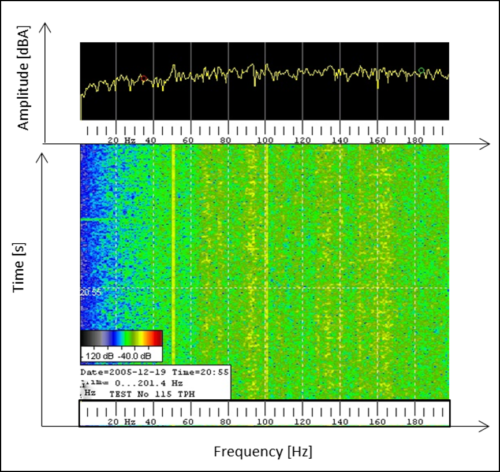

1..The vibration spectra of the background boiler noise is measured separately to the load limiting vibration spectra.

Analysis:

2. The offending frequencies are identified by comparing the boiler background noise spectra against the load limiting vibrations

3. Once identified the offending frequencies are then correlated against the natural frequencies of various boiler components and potential harmonic driving mechanisms within the boiler, which are determined by calculation.

Implementation:

4. Possible strategies to address the disturbance are theoretically evaluated, installed and commissioned.

A case study that demonstrates our capability in this field can be found here.