CAPABILITIES

Heat Recovery Steam Generator [HRSG] Design & Diagnostics

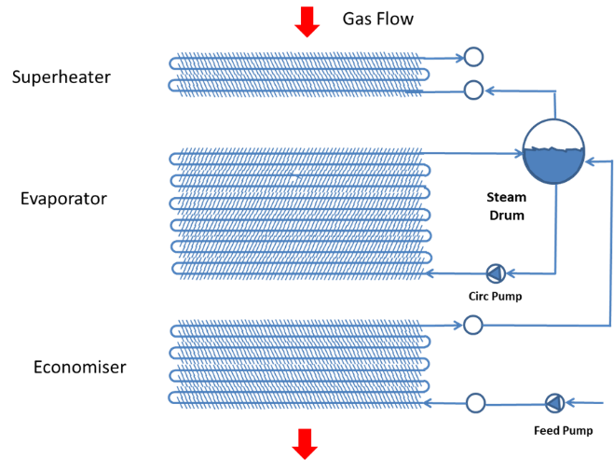

Design Boiler has been involved in the design and diagnostics of HRSG’s for many years. Our technology has also been utilized to verify the suitability of deck mounted HRSGs in key offshore marine installations and to design HRSG’s for industrial co-generation plants.

Our computer software is capable of designing multistage HRSG systems and Waste Heat Recovery Boilers for a wide range of applications. It has also been utilized to design heat recovery systems for industrial, marine and biomass green power applications.

We also have extensive experience in diagnosing problems with existing HRSG plant.

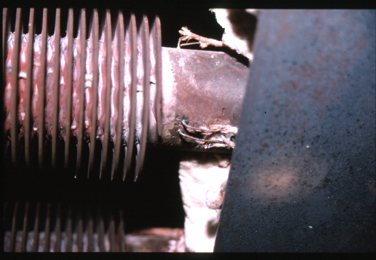

Typical HRSG Failure Scenario:

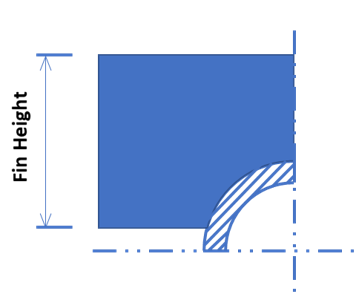

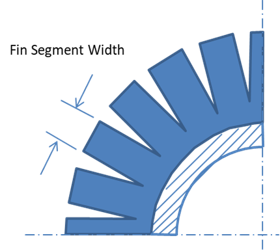

A forced circulation HRSG with horizontal tube banks experiences premature tube fin burn out. A solution is required to improve the longevity of the finned tubes and HRSG.

![Premature tube fin burn out on a Heat Recovery Steam Generator [HRSG]](http://designboiler.com/wp-content/uploads/2019/01/Premature-tube-fin-burn-out-on-a-Heat-Recovery-Steam-Generator-HRSG.jpg)

METHODOLOGY:

Collection of site data:

1..Collect operating data, HRSG geometric and performance details .

HRSG Testing:

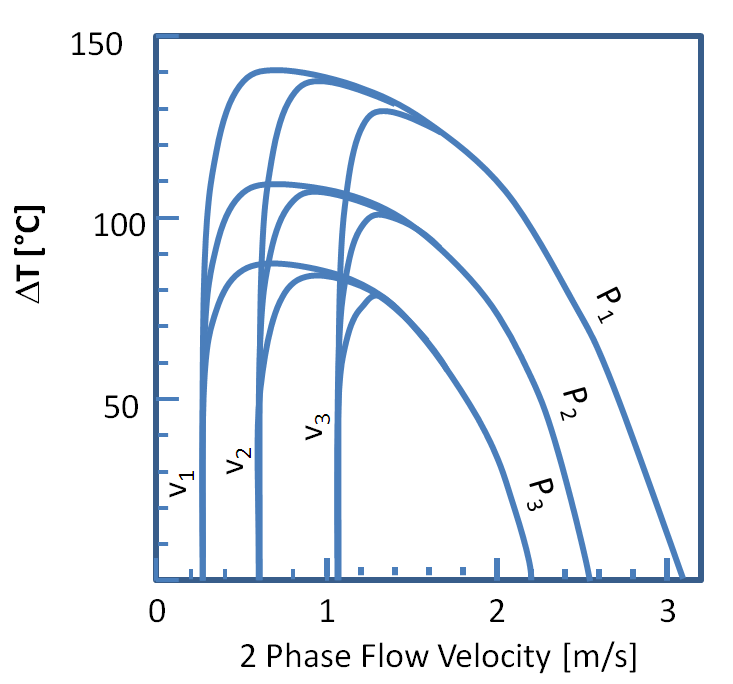

2. Install temporary thermocouples on selected tubes at strategic locations and perform tests at various loads of interest. Measure and record tube DT values as indicated by the temporary thermocouples.

Analysis:

3. High DT values indicate that two phase flow velocity is not sufficient to prevent fin overheating.

4. Undertake computer software modelling of HRSG flow dynamics to simulate a range of two phase flow velocities indicated by the DT measurements at various boiler load configurations. The computer model is utilised to determine the minimum flow required to prevent excessive temperatures at the tips of the tube fins.

5. Typically this problem is best addressed by increasing the two phase flow through the tubes concerned. This is achieved by installing flow balancing restrictors and increasing circulating pump flow capacity.

Implementation:

- Rectification options are assessed by comparing the benefits of flow restrictors and increased circulating pump capacity against the minimum flow requirements determined by the computer flow model. The most effective option is installed, commissioned and subject to performance testing.

- Links to case studies that demonstrate our HRSG and Waste Heat Recovery design and diagnostic capabilities can be found below: